Precision CNC Cutting Services Tailored for Every Industry

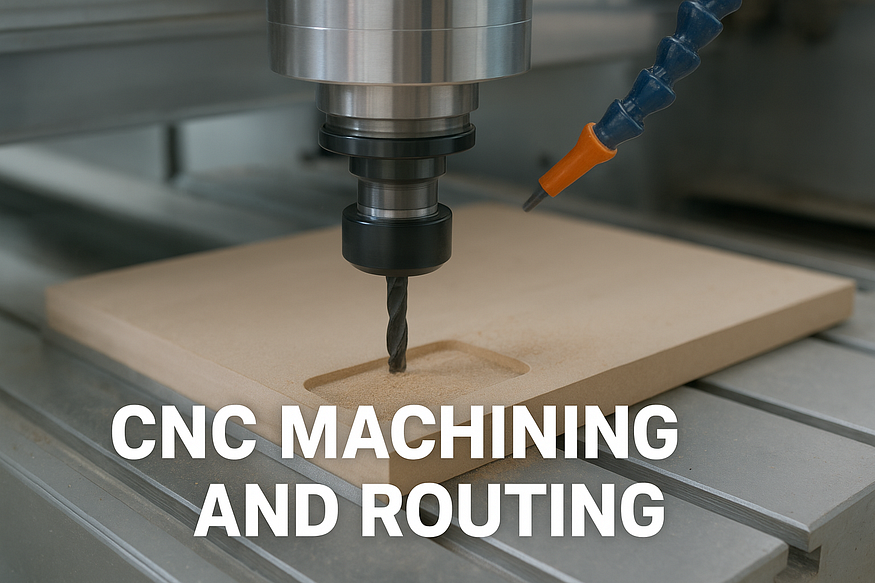

In the world of modern manufacturing and design, CNC cutting services stand as a vital offering for clients who require precision and consistency, whether for prototypes, architectural details, or full-scale production pieces. CNC (Computer Numerical Control) cutting refers to using computer-guided routing or milling machines to carve, engrave, or shape materials with exacting accuracy. Providers like Swordfish Works in London offer laser cutting and CNC cutting as part of their CNC machining services, blending high-end equipment with craftsmanship to deliver quality results.

What Makes CNC Cutting Unique

- Digital Precision: CNC machines follow digital instructions (CAD files), ensuring lines, curves, and edges are cut with very tight tolerances. This means repeatability and minimal variation between pieces — even when making multiple copies.

- Wide Materials Range: From rigid boards like plywood, MDF, and composite panels (e.g., Foamex, Dibond) to softer materials, CNC cutting handles materials of varying densities and hardness. This material flexibility allows clients to choose finishes and textures that best suit their aesthetic and functional needs.

- Complex Geometry: CNC cutting is well-suited to creating 3D shapes, recesses, grooves, and decorative profiles. Whether creating sign trays, retail displays, custom furniture pieces, or sculptural components — CNC offers the versatility to produce complex forms.

Key Advantages of Professional CNC Cutting Services

- Consistency & Quality Control

Because CNC machines run predefined paths automatically, finished parts are consistent. Less manual intervention means fewer errors and more uniform output. - Scalability

Whether you need one prototype or a small batch of dozens, CNC cutting scales well with demand. Once the setup and programming are done, increasing the production run tends to reduce per-unit cost. - Faster Turnaround

Automated CNC cutting shortens lead times — typical manual craftsmanship is replaced by machine paths and programmed sequences. Providers that manage everything in-house — from routing to finishing — can push projects from concept to delivery swiftly. - Reduced Waste & Cost-Efficiency

CNC nesting (strategic layout of shapes on material) helps maximize use of sheet materials, cutting down on waste. Also, the precision means less trimming or finishing is needed after cutting — which saves both time and material.

How Swordfish Works Demonstrates These Benefits

Although exact current technical details weren’t retrievable at the moment, providers like Swordfish Works (via their CNC machining services) are known for:

- Equipped workshops with large-format routers capable of handling significant panel sizes.

- Expertise across both creative and industrial materials — offering solutions for design, signage, interiors, prototypes, and more.

- Supporting clients from design through fabrication — offering advice on material suitability, file preparation, and finish options.

Clients gain an integrated approach where CNC cutting isn’t isolated but part of a broader machining and finishing process. This ensures that cut components are ready for use — whether in retail installations, furniture, display units, or architectural features.

Choosing the Right CNC Cutting Service

When selecting a CNC cutting provider, look for these features:

- Capability to handle your material type and thickness.

- Accuracy specs and tolerance level.

- Maximum panel size and routing/milling capacity.

- Experienced staff who can assist with design optimization.

- Turnaround times aligned with your project deadlines.

- Additional finishing or secondary services (painting, vinyl, assembly) if needed.

Conclusion

CNC cutting services represent a blend of technical precision and material adaptability that make them essential for modern production and design workflows. Providers like those in London — including Swordfish Works — demonstrate how combining large-format CNC routers, material versatility, skilled operators, and design collaboration results in high-quality, cost-effective, and efficient fabrication solutions. Whether for one-off bespoke items or batch production, CNC cutting delivers the reliability and sophistication required by today’s creative and commercial projects.

Original Source: CNC routing London

Comments

Post a Comment